FEW VENTURES ARE AS EXCITING AS THOSE PURSUED IN AN ENVIRONMENT OF CONTINUOUS IMPROVEMENT AND CONSTANT CUSTOMER FEED BACK. THOSE WHO ASPIRE TO THE CHALLENGE OF SUCH OPPORTUNITIES AND EQUIP THEMSELVES ACCORDINGLY ARE REWARDED WITH RARE SUCCESS.

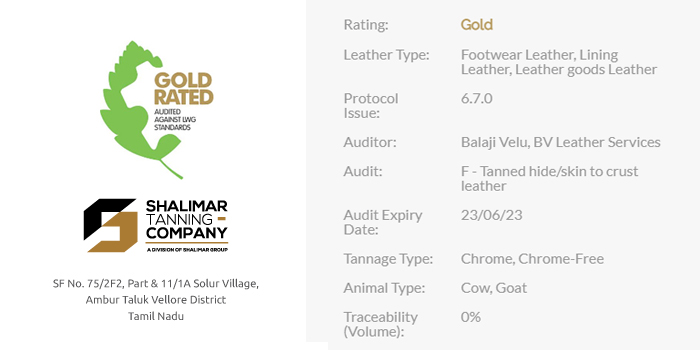

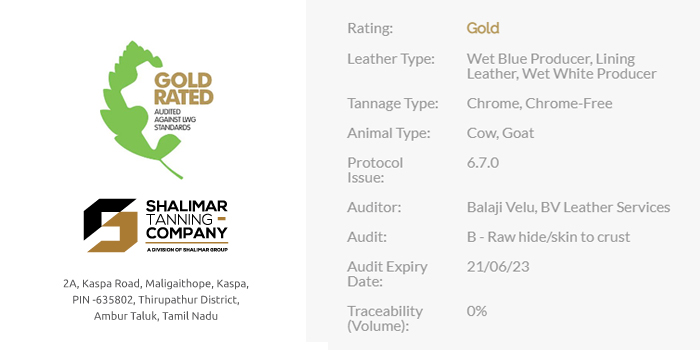

With humble beginnings in 1988, the group’s founder started the company’s first tannery with a leased unit in Ambur. It was primarily into exporting regular finished leathers to the European Market with limited production capacity. Slowly and steadily, Shalimar diversified into fashion finished leathers & footwear manufacturing with seven modern units, outfitted with equipment from Europe and Brazil, and capable of producing 12 million square feet Finished leather every year and 2.1 million pairs of shoes per annum . By the turn of the last decade, our products are sold under popular brand names in more than 20 countries globally.

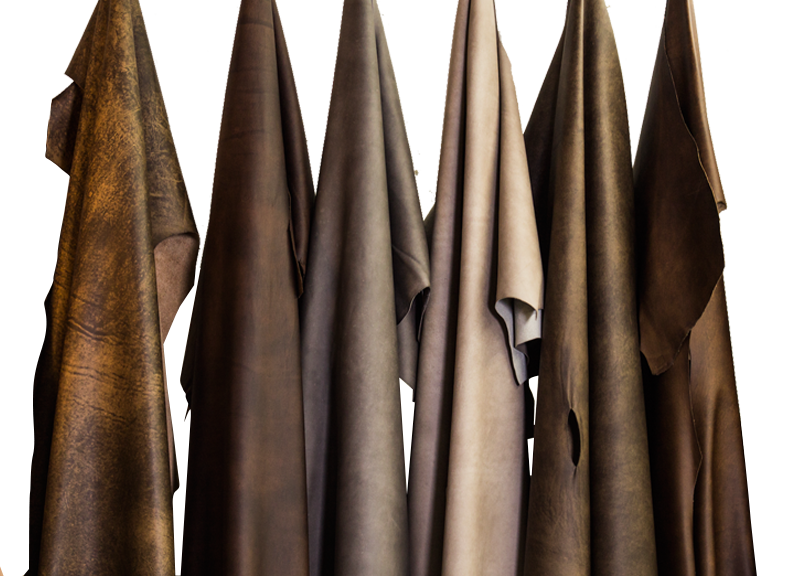

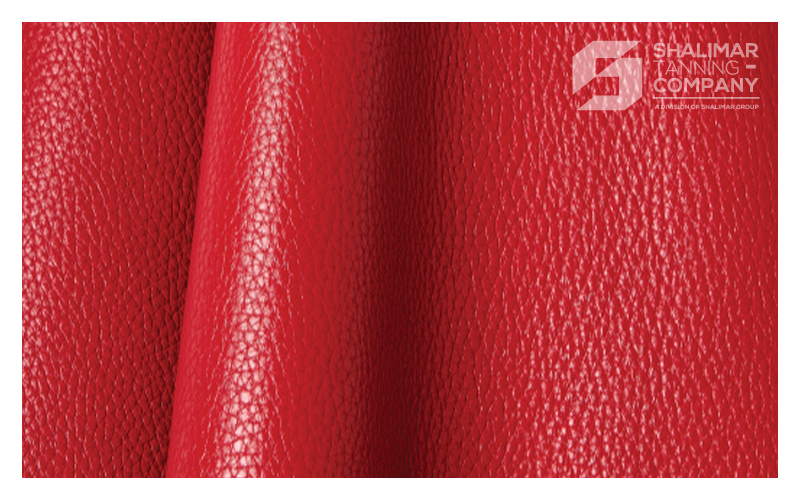

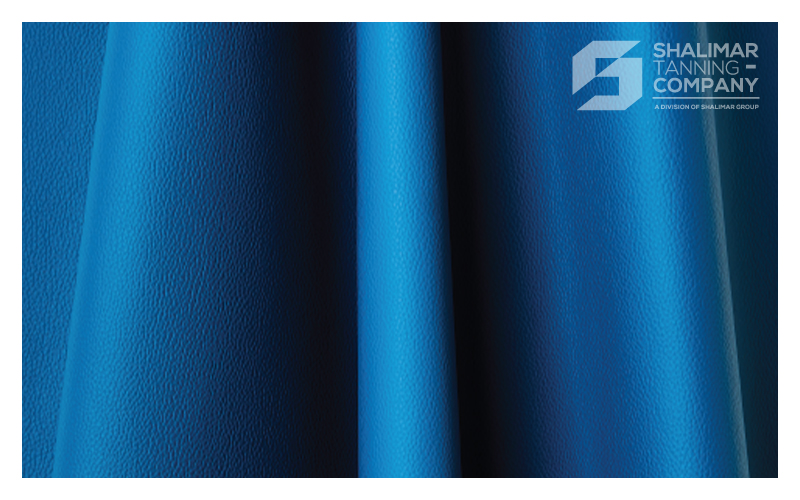

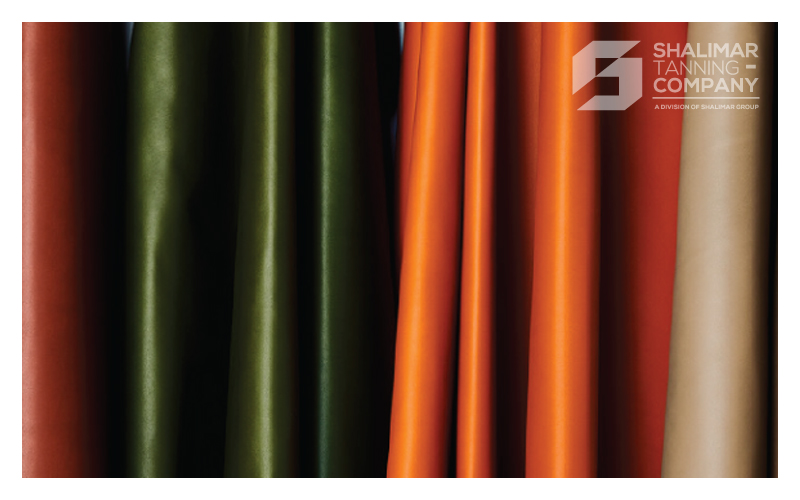

Expeditors ofQuality Finished Leathers

Expeditors ofQuality Finished Leathers

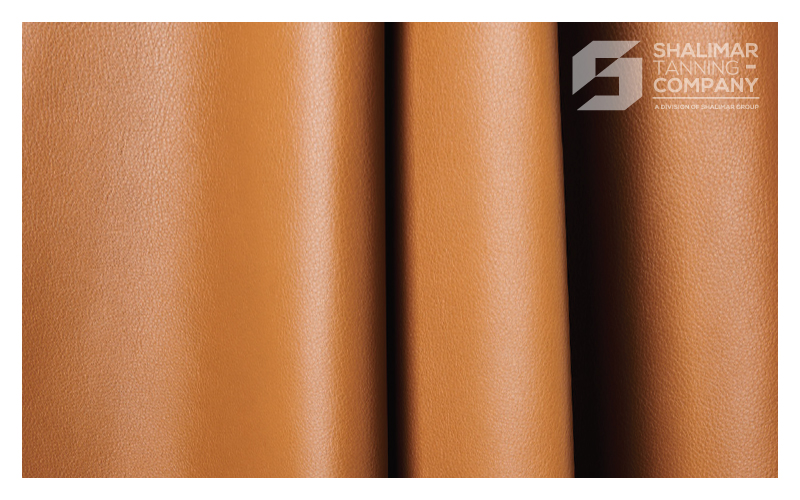

Third Generation ofTanners and Exporters

Third Generation ofTanners and Exporters

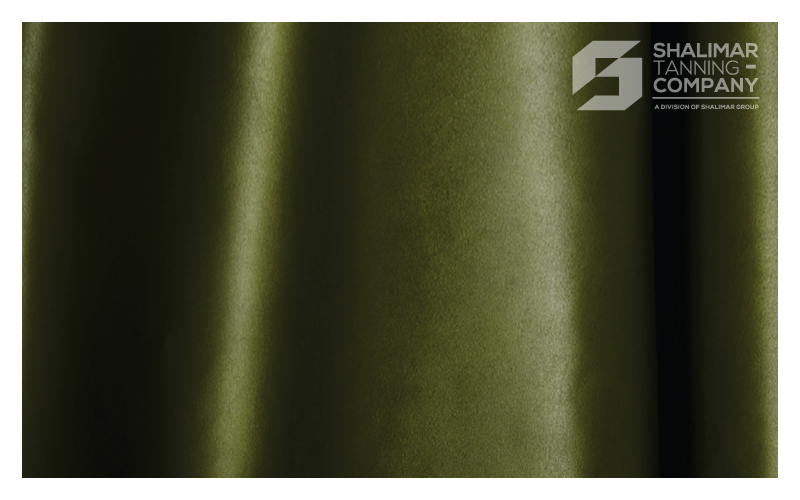

We are ConstantlyFocusing on Innovation

We are ConstantlyFocusing on Innovation